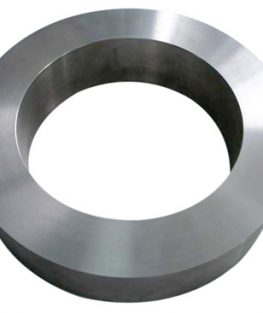

Description

Advantages of tungsten alloy:

Tungsten alloy has many special properties, such as small size with high density, high melting point, high hardness, excellent wear resistance, high ultimate tensile strength, good extension, heat resistant, good thermal stability, easy processing, corrosion resistance, good shock resistance, high radiation absorption capacity, excellent impact and crack resistance.

Tungsten Alloy cylinder Introduction:

Tungsten Cylinders are one of the easiest ways to add weight to your Pinewood Derby Car. With tungsten being 1.7 times denser than lead and over 2 times denser than zinc the Derby Worx Incremental Tungsten Cylinder kit makes adding plenty of weight to your derby car as simple as drilling a hole.

The cylinder offered by us is highly demanded for balancing and weighing cars. Our offered range of cylinder is manufactured with the usage of excellent quality tungsten and cutting-edge technology under the able guidance of our experienced professionals. We provide this Tungsten Alloy Cylinder in different sizes and finishes as per the detailed specified by our reputed clients at nominal rates.

Appliance of tungsten heavy alloy cylinder:

- Usually, tungsten alloy column could be manufactured as the parts of military defense, for penetrating projectiles, counterweights for military defense, projectiles in the missile weapons, armor piercing ammunition, and prefabricated fragments.

- Balance weight: such as Pinewood Derby car counterweight, yacht counterweights, vehicle counterweights, airplane counterweights, helicopter counterweights, boat counterweights, tank counterweights, crankshaft counterweights etc.

Tungsten Heavy Alloy Standards

| ASTM B 777 | Class 1 | Class 2 | Class 3 | Class 4 | |

| Tungsten Nominal % | 90 | 92.5 | 95 | 97 | |

| Density (g/cc) | 16.85-17.25 | 17.15-17.85 | 17.75-18.35 | 18.25-18.85 | |

| Hardeness (HRC) | 32 | 33 | 34 | 35 | |

| Utimate Tensile Strength | ksi | 110 | 110 | 105 | 100 |

| Mpa | 758 | 758 | 724 | 689 | |

| Yield Strength at 0.2% off-set | ksi | 75 | 75 | 75 | 75 |

| Mpa | 517 | 517 | 517 | 517 | |

| Elongation (%) | 5 | 5 | 3 | 2 | |

| AMS-T-21014 | Class 1 | Class 1 | Class 2 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90W7Ni3Fe | 91W6Ni3Fe | 92W5Ni3Fe | 93W4Ni3Fe | 95W3Ni2Fe | 96W3Ni1Fe | 97W2Ni1Fe |

| Density(g/cm3) | 17.1±0.15 | 17.25±0.15 | 17.50±0.15 | 17.60±0.15 | 18.10±0.15 | 18.30±0.15 | 18.50±0.15 |

| Heat Treatment | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering |

| TensileStrength (Mpa) | 900-1000 | 900-1000 | 900-1000 | 900-1000 | 920-1100 | 920-1100 | 920-1100 |

| Elongation (%) | 18-29 | 17-27 | 16-26 | 16-24 | 10-22 | 8-20 | 6-13 |

| Hardness(HRC) | 24-28 | 25-29 | 25-29 | 26-30 | 27-32 | 28-34 | 28-36 |

| Mil-T-21014 | Class1 | Class1 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90%W,

6%Ni4%Cu |

90%W,

7%Ni3%Fe |

92.5%W,5.25%Ni, 2.25%Fe | 95%W, 3.5%Ni

1.5%Cu |

95%W, 3.5%Ni

1.5%Fe |

97%W, 2.1%Ni

0.9%Fe |

| Density(gm/cc;lbs/i3) | 17;0.614 | 17;0.614 | 17.5;0.632 | 18;0.65 | 18;0.65 | 18.5;0.668 |

| Hardness (RC) | 24 | 25 | 26 | 27 | 27 | 28 |

| Ultimate Tensile Strength (PSI) | 110,000 | 120,000 | 114,000 | 110,000 | 120,000 | 123,000 |

| Yield Strength, 2% Offset (PSI) | 80,000 | 88,000 | 84,000 | 85,000 | 90,000 | 85,000 |

| Elongation (% In 1“) | 6 | 10 | 7 | 7 | 7 | 5 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Magnetic Properities | Nil | Slightly | Slightly | Nil | Slightly | Slightly |

| Magnetic | Magnetic | Magnetic | Magnetic | |||

| ASTM-B-459-67 | Grade1 | Grade1 | Grade2 | Grade3 | Grade3 | Grade4 |

We manufacture various grades and sizes of cylinders competely strictly with customer’s request and drawing! We are looking forward to be your supplier!

learn more tungsten products, please contact us !