Description

Advantages of tungsten alloy:

Tungsten alloy has many special properties, such as small size with high density, high melting point, high hardness, excellent wear resistance, high ultimate tensile strength, good extension, heat resistant, good thermal stability, easy processing, corrosion resistance, good shock resistance, high radiation absorption capacity, excellent impact and crack resistance.

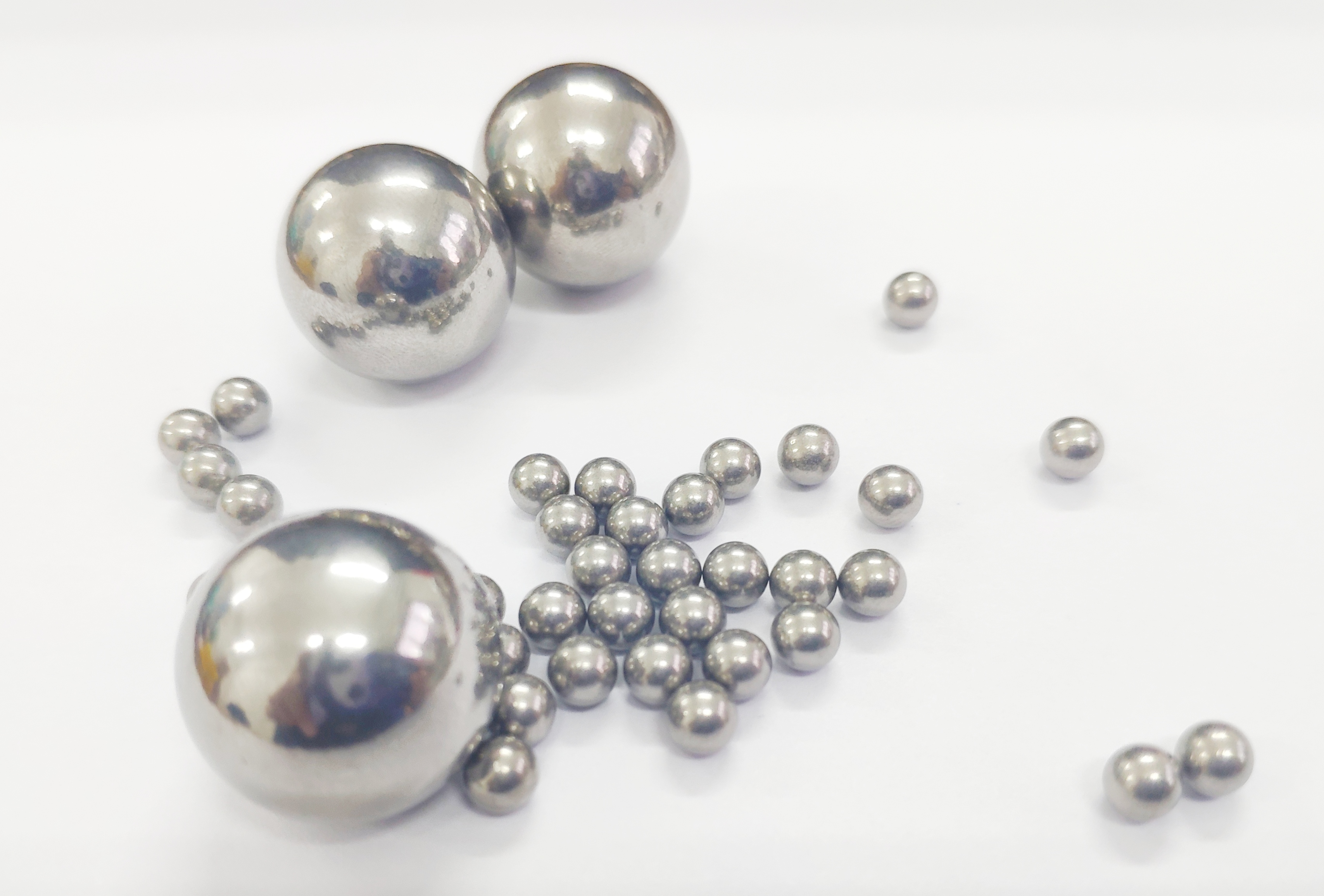

Tungsten Alloy Ball Introduction:

tungsten alloy ball is non-toxic, non-polluting and safer. The high density allows the ball to retain its shape even under extreme conditions. Tungsten alloy ball is small in volume but very dense, which means the product can be used in various fields requiring small but heavy parts, such as fishing weights, hunting pellets, weight for ship, yacht…Heavy tungsten alloy balls or tungsten weight is widely used in weight or balance industrial.

Tungsten alloy balls, tungsten alloy spheres, and tungsten alloy cubes are typically used for fragments in various ammunition products. in military. Compared with lead, such as the missile weapons, armor piercing ammunition. The high density and compatibility make them ideal to create maximum damage within a given packed volume.

Balls we can supply:

- Diameter: 1.0mm-200.0mm

Density: 12.5-18.5 g/cm3

3. Composition: W content: 85-99%, W-Ni-Fe, W-Ni-Cu

4. Surface: Sintered, Forged, Grounded

Tungsten Heavy Alloy Standards

| ASTM B 777 | Class 1 | Class 2 | Class 3 | Class 4 | |

| Tungsten Nominal % | 90 | 92.5 | 95 | 97 | |

| Density (g/cc) | 16.85-17.25 | 17.15-17.85 | 17.75-18.35 | 18.25-18.85 | |

| Hardeness (HRC) | 32 | 33 | 34 | 35 | |

| Utimate Tensile Strength | ksi | 110 | 110 | 105 | 100 |

| Mpa | 758 | 758 | 724 | 689 | |

| Yield Strength at 0.2% off-set | ksi | 75 | 75 | 75 | 75 |

| Mpa | 517 | 517 | 517 | 517 | |

| Elongation (%) | 5 | 5 | 3 | 2 | |

| AMS-T-21014 | Class 1 | Class 1 | Class 2 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90W7Ni3Fe | 91W6Ni3Fe | 92W5Ni3Fe | 93W4Ni3Fe | 95W3Ni2Fe | 96W3Ni1Fe | 97W2Ni1Fe |

| Density(g/cm3) | 17.1±0.15 | 17.25±0.15 | 17.50±0.15 | 17.60±0.15 | 18.10±0.15 | 18.30±0.15 | 18.50±0.15 |

| Heat Treatment | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering |

| TensileStrength (Mpa) | 900-1000 | 900-1000 | 900-1000 | 900-1000 | 920-1100 | 920-1100 | 920-1100 |

| Elongation (%) | 18-29 | 17-27 | 16-26 | 16-24 | 10-22 | 8-20 | 6-13 |

| Hardness(HRC) | 24-28 | 25-29 | 25-29 | 26-30 | 27-32 | 28-34 | 28-36 |

| Mil-T-21014 | Class1 | Class1 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90%W,

6%Ni4%Cu |

90%W,

7%Ni3%Fe |

92.5%W,5.25%Ni, 2.25%Fe | 95%W, 3.5%Ni

1.5%Cu |

95%W, 3.5%Ni

1.5%Fe |

97%W, 2.1%Ni

0.9%Fe |

| Density(gm/cc;lbs/i3) | 17;0.614 | 17;0.614 | 17.5;0.632 | 18;0.65 | 18;0.65 | 18.5;0.668 |

| Hardness (RC) | 24 | 25 | 26 | 27 | 27 | 28 |

| Ultimate Tensile Strength (PSI) | 110,000 | 120,000 | 114,000 | 110,000 | 120,000 | 123,000 |

| Yield Strength, 2% Offset (PSI) | 80,000 | 88,000 | 84,000 | 85,000 | 90,000 | 85,000 |

| Elongation (% In 1“) | 6 | 10 | 7 | 7 | 7 | 5 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Magnetic Properities | Nil | Slightly | Slightly | Nil | Slightly | Slightly |

| Magnetic | Magnetic | Magnetic | Magnetic | |||

| ASTM-B-459-67 | Grade1 | Grade1 | Grade2 | Grade3 | Grade3 | Grade4 |

We manufacture various grades and sizes of balls competely strictly with customer’s request and drawing! We are looking forward to be your supplier!

learn more tungsten balls, please contact us !