Description

Advantages of tungsten alloy:

Tungsten alloy has many special properties, such as small size with high density, high melting point, high hardness, excellent wear resistance, high ultimate tensile strength, good extension, heat resistant, good thermal stability, easy processing, corrosion resistance, good shock resistance, high radiation absorption capacity, excellent impact and crack resistance.

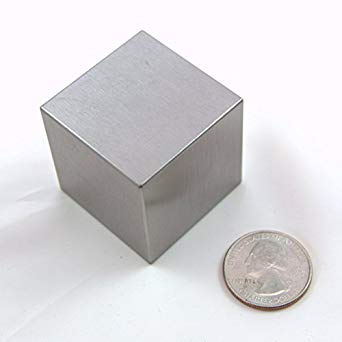

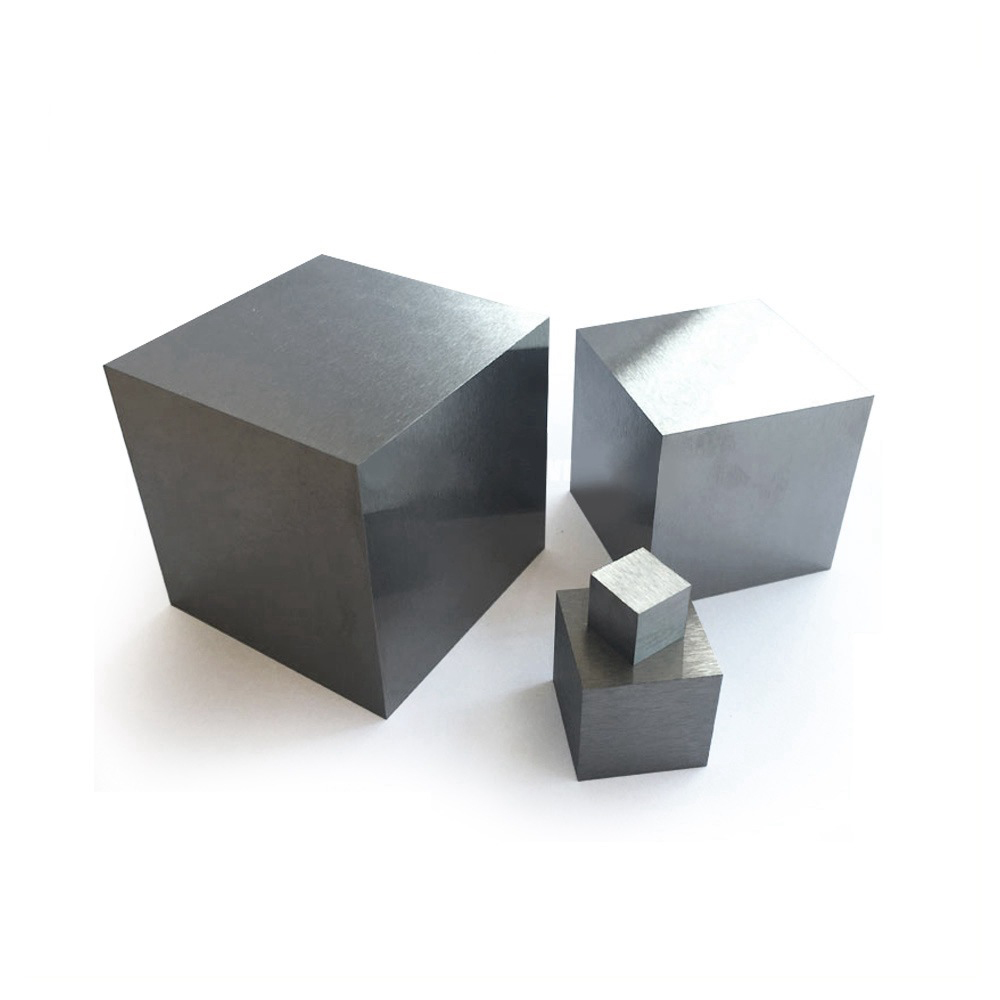

Tungsten Alloy cube Introduction:

1.Applications of Tungsten Alloy Cubes:

Tungsten heavy alloy cube is completely non-toxic and environmentally friendly so tungsten heavy alloy cube is often used in weighting applications, especially used in pine wood derby cube to offer a pinewood derby kits. where lead is not appropriate. For example, lead has been banned in many streams, so tungsten heavy alloy cube is often substituted for lead weight on fishing flies. The high density of tungsten heavy alloy cube coupled with the non-toxic nature makes tungsten heavy alloy cube an ideal metal for this application.

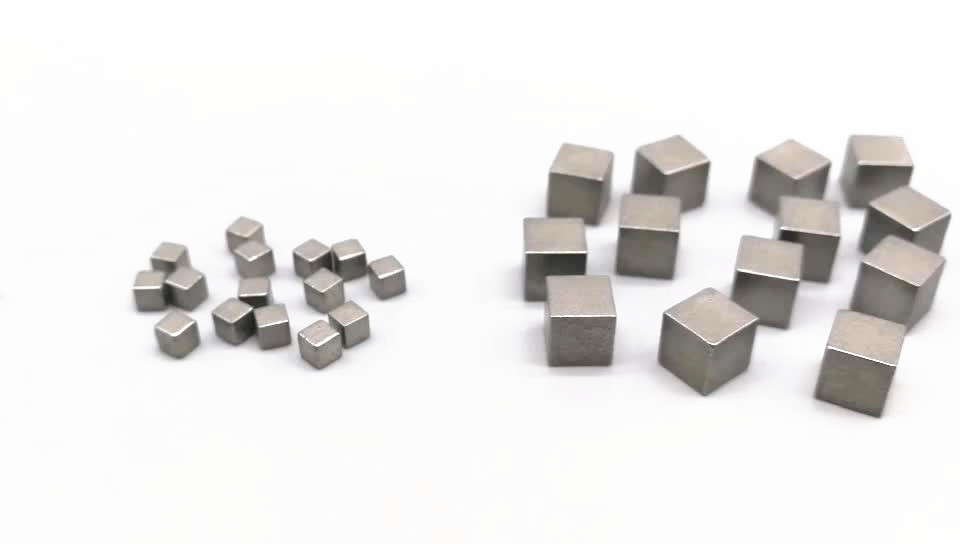

2 .Tungsten cube we usual supply:

6.35*6.35*6.35mm (0.25 ” tungsten cube) 10*10*10mm

12.7*12.7*12.7mm (0.5 ” tungsten cube) 20*20*20mm

25.4*25.4*25.4mm (1.0 ” tungsten cube) 38.1*38.1*38.1mm (1.5″ tungsten cube)

47*47*47mm(2kg tungsten cube) 51*51*51mm(2.5kg tungsten cube)

54.5*54.5*54.5mm(3kg tungsten cube) 103*103*103mm(20kg tungsten cube)

We also could supply sizes as customer’s requirements.

Tungsten Heavy Alloy Standards

| ASTM B 777 | Class 1 | Class 2 | Class 3 | Class 4 | |

| Tungsten Nominal % | 90 | 92.5 | 95 | 97 | |

| Density (g/cc) | 16.85-17.25 | 17.15-17.85 | 17.75-18.35 | 18.25-18.85 | |

| Hardeness (HRC) | 32 | 33 | 34 | 35 | |

| Utimate Tensile Strength | ksi | 110 | 110 | 105 | 100 |

| Mpa | 758 | 758 | 724 | 689 | |

| Yield Strength at 0.2% off-set | ksi | 75 | 75 | 75 | 75 |

| Mpa | 517 | 517 | 517 | 517 | |

| Elongation (%) | 5 | 5 | 3 | 2 | |

| AMS-T-21014 | Class 1 | Class 1 | Class 2 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90W7Ni3Fe | 91W6Ni3Fe | 92W5Ni3Fe | 93W4Ni3Fe | 95W3Ni2Fe | 96W3Ni1Fe | 97W2Ni1Fe |

| Density(g/cm3) | 17.1±0.15 | 17.25±0.15 | 17.50±0.15 | 17.60±0.15 | 18.10±0.15 | 18.30±0.15 | 18.50±0.15 |

| Heat Treatment | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering |

| TensileStrength (Mpa) | 900-1000 | 900-1000 | 900-1000 | 900-1000 | 920-1100 | 920-1100 | 920-1100 |

| Elongation (%) | 18-29 | 17-27 | 16-26 | 16-24 | 10-22 | 8-20 | 6-13 |

| Hardness(HRC) | 24-28 | 25-29 | 25-29 | 26-30 | 27-32 | 28-34 | 28-36 |

| Mil-T-21014 | Class1 | Class1 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90%W,

6%Ni4%Cu |

90%W,

7%Ni3%Fe |

92.5%W,5.25%Ni, 2.25%Fe | 95%W, 3.5%Ni

1.5%Cu |

95%W, 3.5%Ni

1.5%Fe |

97%W, 2.1%Ni

0.9%Fe |

| Density(gm/cc;lbs/i3) | 17;0.614 | 17;0.614 | 17.5;0.632 | 18;0.65 | 18;0.65 | 18.5;0.668 |

| Hardness (RC) | 24 | 25 | 26 | 27 | 27 | 28 |

| Ultimate Tensile Strength (PSI) | 110,000 | 120,000 | 114,000 | 110,000 | 120,000 | 123,000 |

| Yield Strength, 2% Offset (PSI) | 80,000 | 88,000 | 84,000 | 85,000 | 90,000 | 85,000 |

| Elongation (% In 1“) | 6 | 10 | 7 | 7 | 7 | 5 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Magnetic Properities | Nil | Slightly | Slightly | Nil | Slightly | Slightly |

| Magnetic | Magnetic | Magnetic | Magnetic | |||

| ASTM-B-459-67 | Grade1 | Grade1 | Grade2 | Grade3 | Grade3 | Grade4 |

We manufacture various grades and sizes of cubes competely strictly with customer’s request and drawing! We are looking forward to be your supplier!

learn more tungsten products, please contact us !