Description

Advantages of tungsten alloy:

Tungsten alloy has many special properties, such as small size with high density, high melting point, high hardness, excellent wear resistance, high ultimate tensile strength, good extension, heat resistant, good thermal stability, easy processing, corrosion resistance, good shock resistance, high radiation absorption capacity, excellent impact and crack resistance.

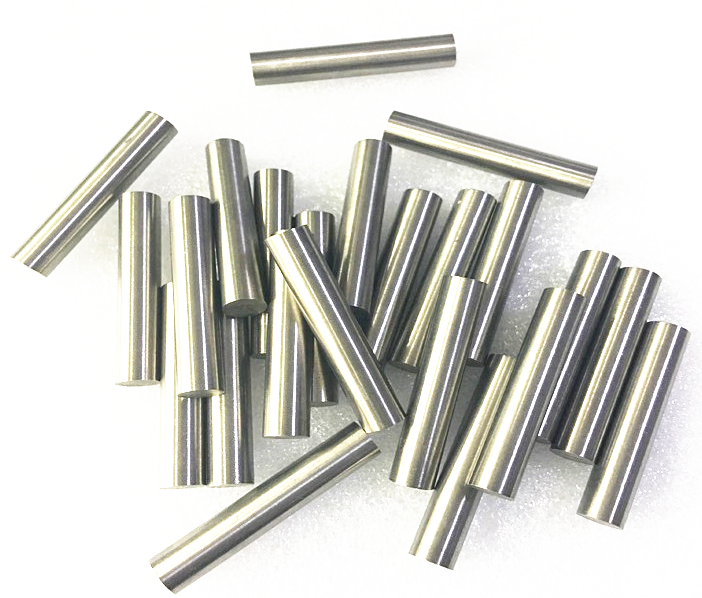

Tungsten alloy dart billets Introduction:

Tungsten dart billets are the rods used for making dart barrels. Today’s standard material for barrel is tungsten heavy alloy, and barrel forms the main part of a dart (mainly used in sports).

Tungsten has a specific gravity of 19.3(20 ℃ ), so it is a very dense material. For its special properties, nowadays tungsten is widely applied to make darts replacing brass. Because of technical difficulties with manufacturing, a 100% tungsten dart is not available. All “tungsten” darts you can buy are in fact made of tungsten heavy alloy.

We could supply tungsten dart billets by various sizes and contents, popularly 70~90% tungsten dart billets are used for making both soft-tip and steel tip tungsten barrels, ranging from 14~18 gram and 18~40 gram respectively, and sometimes, 65% and 95~97% tungsten are offered following customers’ specific request.

Regular Tungsten Alloy Billets Size:

| Tungsten Heavy Alloy Billet Size

[Ø(+0.05)×(+1.0)mm] |

Content of W (%) | |||||||

| 70 | 80 | 85 | 90 | 95 | 97 | |||

| Density (+/-0.15g/cc) | ||||||||

| 13.90 | 15.40 | 16.00 | 16.90 | 18.00 | 18.5 | |||

| No. | inch | mm | Weight (+/-0.50g/pc) | |||||

| 1 | Ø1/4×1.7 | Ø6.35×43.2 | ||||||

| 2 | Ø1/4×1.8 | Ø6.35×45.7 | ||||||

| 3 | Ø1/4×1.9 | Ø6.35×48.3 | ||||||

| 4 | Ø1/4×2.00 | Ø6.35×50.8 | ||||||

| 5 | Ø1/4×2.15 | Ø6.35×54.6 | ||||||

| 6 | Ø0.265×1.7 | Ø6.73×43.2 | ||||||

| 7 | Ø0.265×1.8 | Ø6.73×45.7 | ||||||

| 8 | Ø0.265×1.9 | Ø6.73×48.3 | ||||||

| 9 | Ø0.265×2.00 | Ø6.73×50.8 | ||||||

| 10 | Ø0.265×2.15 | Ø6.73×54.6 | ||||||

| 11 | Ø9/32×1.6 | Ø7.15×40.7 | ||||||

| 12 | Ø9/32×1.7 | Ø7.15×43.2 | ||||||

| 13 | Ø9/32×1.8 | Ø7.15×45.7 | ||||||

| 14 | Ø9/32×1.9 | Ø7.15×48.3 | ||||||

| 15 | Ø9/32×2.00 | Ø7.15×50.8 | ||||||

| 16 | Ø9/32×2.15 | Ø7.15×54.6 | ||||||

| 17 | Ø5/16×1.6 | Ø7.94×40.7 | ||||||

| 18 | Ø5/16×1.7 | Ø7.94×43.2 | ||||||

| 19 | Ø5/16×1.8 | Ø7.94×45.7 | ||||||

| 20 | Ø5/16×1.9 | Ø7.94×48.3 | ||||||

| 21 | Ø5/16×2.00 | Ø7.94×50.8 | ||||||

| 22 | Ø11/32×1.4 | Ø8.74×35.6 | ||||||

| 23 | Ø11/32×1.6 | Ø8.74×40.7 | ||||||

| 24 | Ø11/32×1.8 | Ø8.74×45.7 | ||||||

| 25 | Ø11/32×2.00 | Ø8.74×50.8 | ||||||

Any size or tungsten content unavailable from this above table can also be manufactured in accordance with your specifications. Please contact us for a price and other information about tungsten alloy dart.

Tungsten Heavy Alloy Standards

| ASTM B 777 | Class 1 | Class 2 | Class 3 | Class 4 | |

| Tungsten Nominal % | 90 | 92.5 | 95 | 97 | |

| Density (g/cc) | 16.85-17.25 | 17.15-17.85 | 17.75-18.35 | 18.25-18.85 | |

| Hardeness (HRC) | 32 | 33 | 34 | 35 | |

| Utimate Tensile Strength | ksi | 110 | 110 | 105 | 100 |

| Mpa | 758 | 758 | 724 | 689 | |

| Yield Strength at 0.2% off-set | ksi | 75 | 75 | 75 | 75 |

| Mpa | 517 | 517 | 517 | 517 | |

| Elongation (%) | 5 | 5 | 3 | 2 | |

| AMS-T-21014 | Class 1 | Class 1 | Class 2 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90W7Ni3Fe | 91W6Ni3Fe | 92W5Ni3Fe | 93W4Ni3Fe | 95W3Ni2Fe | 96W3Ni1Fe | 97W2Ni1Fe |

| Density(g/cm3) | 17.1±0.15 | 17.25±0.15 | 17.50±0.15 | 17.60±0.15 | 18.10±0.15 | 18.30±0.15 | 18.50±0.15 |

| Heat Treatment | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering | Sintering |

| TensileStrength (Mpa) | 900-1000 | 900-1000 | 900-1000 | 900-1000 | 920-1100 | 920-1100 | 920-1100 |

| Elongation (%) | 18-29 | 17-27 | 16-26 | 16-24 | 10-22 | 8-20 | 6-13 |

| Hardness(HRC) | 24-28 | 25-29 | 25-29 | 26-30 | 27-32 | 28-34 | 28-36 |

| Mil-T-21014 | Class1 | Class1 | Class 2 | Class 3 | Class 3 | Class 4 |

| Composition | 90%W,

6%Ni4%Cu |

90%W,

7%Ni3%Fe |

92.5%W,5.25%Ni, 2.25%Fe | 95%W, 3.5%Ni

1.5%Cu |

95%W, 3.5%Ni

1.5%Fe |

97%W, 2.1%Ni

0.9%Fe |

| Density(gm/cc;lbs/i3) | 17;0.614 | 17;0.614 | 17.5;0.632 | 18;0.65 | 18;0.65 | 18.5;0.668 |

| Hardness (RC) | 24 | 25 | 26 | 27 | 27 | 28 |

| Ultimate Tensile Strength (PSI) | 110,000 | 120,000 | 114,000 | 110,000 | 120,000 | 123,000 |

| Yield Strength, 2% Offset (PSI) | 80,000 | 88,000 | 84,000 | 85,000 | 90,000 | 85,000 |

| Elongation (% In 1“) | 6 | 10 | 7 | 7 | 7 | 5 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Magnetic Properities | Nil | Slightly | Slightly | Nil | Slightly | Slightly |

| Magnetic | Magnetic | Magnetic | Magnetic | |||

| ASTM-B-459-67 | Grade1 | Grade1 | Grade2 | Grade3 | Grade3 | Grade4 |

We manufacture various grades and sizes of tungsten dart billets competely strictly with customer’s request and drawing! We are looking forward to be your supplier!

learn more tungsten balls, please contact us !