The tungsten carbide button exists and is known among the most demanded mining bits’ tools in present industries, thus usually called tungsten carbide button bits, tungsten carbide mining bits, or just tungsten carbide mining buttons.

Since its comprise of cemented carbide, so cemented carbide buttons are also frequently used among users. Because of its unique working exhibition, tungsten carbide catches are generally utilized in snow expulsion, oil field penetrating, and snowplow machines or gear.

Then again, established carbide catches are utilized in street support instruments, coal shaper boring devices, mine apparatus devices, snow clearing, and street-cleaning. Carbide mining button pieces are primarily applied for rock contraptions, mining instruments used in quarrying, mining, burrowing, and expected developments.

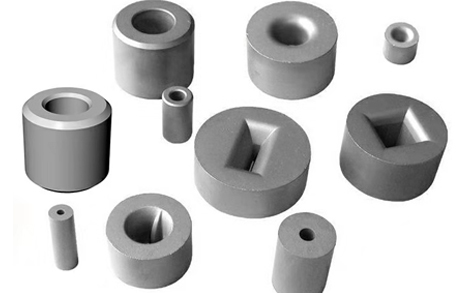

Types of Cemented Carbide Buttons

As per the diverse oil-field boring apparatus, for example, roller cone bits, DTH bits, geotechnical penetrating devices, vagabond pieces, tungsten carbide mining b is partitioned into various standard styles;

- P-type flat-top bits

- Z type coin spherical bits

- X type wedge bits

The main advantage of making tungsten carbide button bits is that manufacturers use HIP sintering to diminish apparent carbide porosity to increment cross-over crack strength (TRS). It is entirely appropriate for an excellent prerequisite for making carbide catches in high and medium pressing factors, DTH Drilling.

There is a ton of data inside the tungsten market, from understanding carbide reusing materials to realizing how to manage your tungsten scrap. Ideally, these realities will assist you with bettering comprehend the intricate details of the tungsten business.

In the light of the following facts underneath, it’ll be more obvious to fathom Tungsten alongside its historical significance and properties;

- Historical Significance— It’s been around 236 years since Tungsten was first discovered in 1781, and till 1931 any industry couldn’t find any specific use for this durable metal.

- Properties — Tungsten is glossy and can be effortlessly handled. However, it is challenging; Tungsten can show up as its standard structure when combined with calcium, iron, or manganese mineral structures.

- Melting & Boiling point — The limit of Tungsten is 10,030 degrees Fahrenheit (5,555 degrees Calvin) and has the most elevated liquefying point of all realized metals on earth, 6,191 degrees Fahrenheit (3,422 degrees Calvin).

- Global tungsten supply — The U.S. has a solid inventory of Tungsten and buys and reuses it frequently, yet numerous different nations are head Tungsten creating nations. Austria, Peru, Portugal, Russia, and Bolivia stay high makers.

Australia, Japan, France, Sweden, Brazil, and a couple of more nations have seen a sharp decrease in their tungsten creation as mines have kept shutting.

- Recycling — Tungsten carbide reusing materials are fantastic wellsprings of money on the off chance that you go over a wealth of tungsten carbide muck. Regardless of whether it’s carbide embeds or more extensive parts of tungsten scrap, this metal is pursued by organizations from one side of the planet to the other, and I couldn’t imagine anything better than to pay you for your carbide reusing materials.

- Applications — Everything from TVs, instruments, microwaves, adornments, development occupations, and a wide range of ventures need Tungsten.

- Hardness — Tungsten carbide falls simply behind precious stones on the Moh’s hardness scale at 8.5 to 9 (jewels have a hardness of 10). Tungsten is entirely the solidness and thickness of the steel.