The shielding of tungsten radiation is one of the best materials for shielding. It keeps the exposure of radiation minimum. A common question raised, why tungsten radiation shielding is used? The reason is that this shielding has a density of up to 18.89 g/cm3 and also lead at 11.34 g/cm3. Tungsten shielding is the ease of machining or mechanical processing, it provides high ductility and strength which makes it a feasible option for many applications. Moreover, it is strong and extremely customizable to precision components. It provides superior attenuation characteristics for x-ray and gamma radiation as it is denser material.

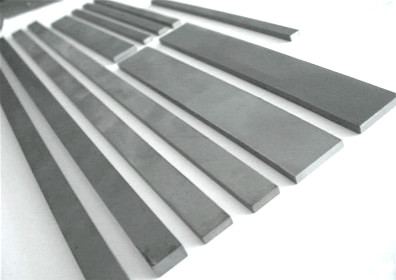

The superior attenuation of high-density tungsten radiation shielding gives designers a significant advantage. This characteristic permits the reduction of shield thickness and collimators whereas it also provides protection like lead which is ideal for many applications. Tungsten alloy machined with conventional CNC machines which allow manufacturing a wide range to customer requirements. Many of the fields require tungsten radiation shielding or tungsten collimators because of their high-density feature. They can produce a variety of forms like parallels, dual resolution, multi-pinhole, and divergent from tungsten collimators. Let’s discuss some filed where tungsten is using on high demand:

Medical field:

In nuclear medicine, tungsten radiation is used for diagnostics and therapeutic applications. In both cases, tungsten alloy offers the perfect solution to collimators and radiation shielding. The latest preclinical studies showed that 3D printed tungsten collimators produce an improved quality of image dramatically. The tungsten collimator emits direct radiation to the subject onto a detector which minimizes the stray photons number. Its alloy is resistant to surface chips and dents which makes it easy to clean and sterilize. Tungsten is highly used in the field of medicine.

Industrial use:

The tungsten alloy’s strength and durability allow us to withstand the harsh environment of the industry. Tungsten alloy’s high density gives excellent radiation attenuation that’s why its use in industries as it produces a wide variety of shapes. Moreover, its high density allows the creation of industrial custom-designed shields. The tungsten alloy is ideal for use in collimators and shields both to protect personnel operation from any possible exposure to the gamma rays. In this application, tungsten alloy use to detect potential oil and gas deposits, also help ensure accuracy in the data collection and measurements. Moreover, tungsten alloy collimators ensure radiation beams focus on the area being inspected accurately. The high density of tungsten allows industrial designers to reduce the shielding thickness with the same level of protection.

Nuclear engineering:

Tungsten alloy used to provide effective shielding in the nuclear engineering applications range against harmful radiation. Without compromising the protection level for personnel and sensitive equipment, it is used for small localized shields in restricted spaces because of excellent attenuation properties. The spent nuclear fuel and nuclear waste materials are exposed to investigate procedures to determine the content of radionuclide. Tungsten alloy is perfect for shielding material in small space use like around pipelines in this field where liquid or gas through-flow needs to monitor.