Have this question ever cross your mind that why tungsten is best for shielding, or radiation shielding? I think many individuals would have to think about it, the answer is, Tungsten shielding or tungsten radiation Shielding has a high density up to 18.89 g/cm3 vs. lead at 11.34 g/cm3.

For this reason, the use of tungsten in process of radiation shielding makes mechanical processing/machining much easier with high strength and ductility. This makes it a more feasible option for various applications where lead is not possible to use wither due to size reduction, increased weight in large or small cavities, or for radiation shielding.

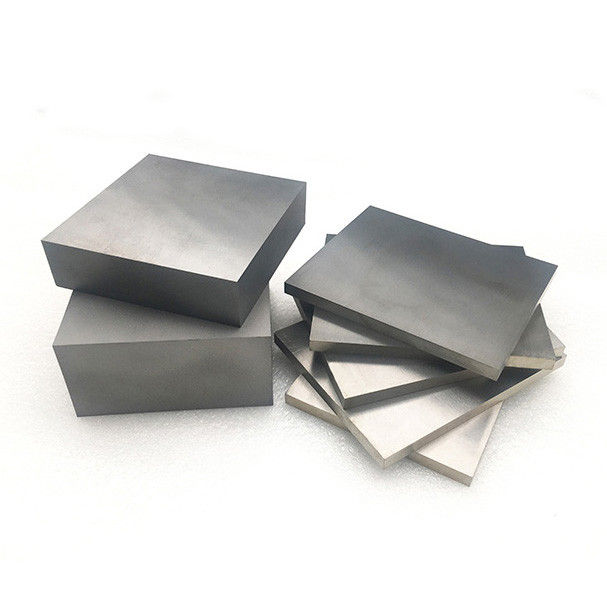

Thus, the Tungsten Radiation Shielding in these applications stays strong and can be customized as accurately required in components. On the other hand, the reason for choosing tungsten alloy shielding that is rich in greater density is, that tungsten alloy has the best capacity for absorbing rays, high density (double density likewise found in lead), as well as strongly resistant against corrosion.

What is the Advantage of Tungsten Alloy Shielding that has high density?

The main advantage is, the properties of tungsten shielding radiation are closely related to the density of shielding material. Higher density indicates better chances of ray absorption and good ability of radiation shielding ability.

The tungsten alloy has a higher density unlike other materials, has a better ability of ray absorption and block ability which is quite better than other traditional shielding materials, such as lead.

Another advantage of using greater density tungsten alloy shielding is, it performs better shielding on gamma rays, which can result in reducing the volume of shielding. If we compare with lead in the same volume, then high-density tungsten alloy shielding proved to have better radiation shielding.

With this amalgamation of high density, good corrosion resistance, machinability, and high radiation absorption capability (greater than steel and lead), and high strength, the tungsten alloy is thus justified as the best material for shielding.

Though it has been proved to be the best source for radiation shielding, yet the Tungsten alloy shielding has the same radiation shielding ability alike lead even when dropped in volume, and thickness of container. Also, as compared to lead and depleted uranium, high-density tungsten alloy is more eco – friendly for its pollution-free and non-toxic property. Let’s move to striking use or application of tungsten alloy shielding.

What is the best Application for Tungsten Alloy Shielding?

Since the tungsten allows shielding material isn’t subjected to NRC, EPA, and the OSHA regulations of special constraints due to its greater density, thus, tungsten shielding, allows shielding material is widely used in nuclear medicine as container radioactive isotope, collimator, and radiation source container, etc.